Ultimate Guide to Thin Wall Deep Groove Ball Bearings: Design and Construction Explained

Time:

2024-04-27

---

**Introduction**

Thin wall deep groove ball bearings are essential components in various industries, including automotive and machinery. Understanding their design and construction is crucial for ensuring optimal performance and longevity. In this guide, we will delve into the intricacies of thin wall deep groove ball bearings, exploring their construction, materials, and applications.

---

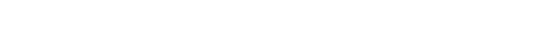

**What are Thin Wall Deep Groove Ball Bearings?**

Thin wall deep groove ball bearings are precision-engineered components used to facilitate smooth rotation in machinery and automotive systems. These bearings feature a deep groove design, allowing them to accommodate both radial and axial loads. Their thin wall construction makes them ideal for applications where space is limited or weight reduction is crucial.

---

**Design Principles of Thin Wall Deep Groove Ball Bearings**

The design of thin wall deep groove ball bearings is based on several key principles. These bearings typically consist of an inner and outer ring, a cage, and a series of balls. The design allows for efficient load distribution and reduced friction, resulting in smooth and reliable operation.

---

**Construction Materials**

Thin wall deep groove ball bearings are commonly constructed from high-quality materials such as stainless steel, chrome steel, or ceramic. These materials are chosen for their durability, corrosion resistance, and ability to withstand high temperatures. The choice of construction material depends on the specific application requirements and environmental conditions.

---

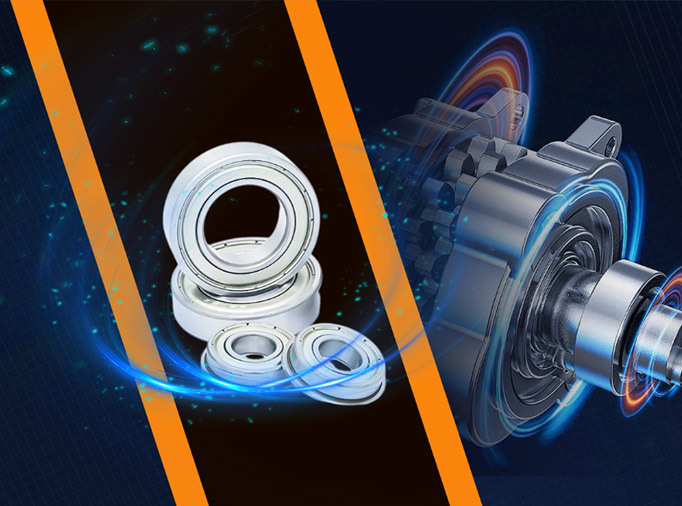

**Applications of Thin Wall Deep Groove Ball Bearings**

Thin wall deep groove ball bearings are used in a wide range of applications, including automotive transmissions, electric motors, and industrial machinery. Their compact design and high load capacity make them suitable for situations where space is limited or weight reduction is essential. These bearings play a critical role in ensuring smooth and efficient operation of various mechanical systems.

---

**Advantages of Thin Wall Deep Groove Ball Bearings**

- Compact design

- High load capacity

- Low friction

- Reduced noise and vibration

- Long service life

---

**Challenges in Designing Thin Wall Deep Groove Ball Bearings**

Despite their numerous advantages, designing thin wall deep groove ball bearings comes with its own set of challenges. Ensuring optimal load distribution, minimizing friction, and maintaining structural integrity are key considerations in the design process. Engineers must carefully balance these factors to create bearings that meet the performance requirements of the application.

---

**FAQs**

1. What are the main components of thin wall deep groove ball bearings?

2. How do thin wall deep groove ball bearings differ from standard ball bearings?

3. What materials are commonly used in the construction of thin wall deep groove ball bearings?

4. What are the key advantages of using thin wall deep groove ball bearings in automotive applications?

5. How can proper maintenance prolong the service life of thin wall deep groove ball bearings?

---

**Conclusion**

In conclusion, thin wall deep groove ball bearings are essential components in various industries, providing smooth and reliable operation in automotive and machinery applications. Understanding the design and construction of these bearings is crucial for ensuring optimal performance and longevity. By exploring the principles, materials, and applications of thin wall deep groove ball bearings, engineers and technicians can make informed decisions when selecting and utilizing these critical components.

**Introduction**

Thin wall deep groove ball bearings are essential components in various industries, including automotive and machinery. Understanding their design and construction is crucial for ensuring optimal performance and longevity. In this guide, we will delve into the intricacies of thin wall deep groove ball bearings, exploring their construction, materials, and applications.

---

**What are Thin Wall Deep Groove Ball Bearings?**

Thin wall deep groove ball bearings are precision-engineered components used to facilitate smooth rotation in machinery and automotive systems. These bearings feature a deep groove design, allowing them to accommodate both radial and axial loads. Their thin wall construction makes them ideal for applications where space is limited or weight reduction is crucial.

---

**Design Principles of Thin Wall Deep Groove Ball Bearings**

The design of thin wall deep groove ball bearings is based on several key principles. These bearings typically consist of an inner and outer ring, a cage, and a series of balls. The design allows for efficient load distribution and reduced friction, resulting in smooth and reliable operation.

---

**Construction Materials**

Thin wall deep groove ball bearings are commonly constructed from high-quality materials such as stainless steel, chrome steel, or ceramic. These materials are chosen for their durability, corrosion resistance, and ability to withstand high temperatures. The choice of construction material depends on the specific application requirements and environmental conditions.

---

**Applications of Thin Wall Deep Groove Ball Bearings**

Thin wall deep groove ball bearings are used in a wide range of applications, including automotive transmissions, electric motors, and industrial machinery. Their compact design and high load capacity make them suitable for situations where space is limited or weight reduction is essential. These bearings play a critical role in ensuring smooth and efficient operation of various mechanical systems.

---

**Advantages of Thin Wall Deep Groove Ball Bearings**

- Compact design

- High load capacity

- Low friction

- Reduced noise and vibration

- Long service life

---

**Challenges in Designing Thin Wall Deep Groove Ball Bearings**

Despite their numerous advantages, designing thin wall deep groove ball bearings comes with its own set of challenges. Ensuring optimal load distribution, minimizing friction, and maintaining structural integrity are key considerations in the design process. Engineers must carefully balance these factors to create bearings that meet the performance requirements of the application.

---

**FAQs**

1. What are the main components of thin wall deep groove ball bearings?

2. How do thin wall deep groove ball bearings differ from standard ball bearings?

3. What materials are commonly used in the construction of thin wall deep groove ball bearings?

4. What are the key advantages of using thin wall deep groove ball bearings in automotive applications?

5. How can proper maintenance prolong the service life of thin wall deep groove ball bearings?

---

**Conclusion**

In conclusion, thin wall deep groove ball bearings are essential components in various industries, providing smooth and reliable operation in automotive and machinery applications. Understanding the design and construction of these bearings is crucial for ensuring optimal performance and longevity. By exploring the principles, materials, and applications of thin wall deep groove ball bearings, engineers and technicians can make informed decisions when selecting and utilizing these critical components.

Related recommend

Share