FAQ

Robotics, medical equipment, aerospace equipment, camera and optical equipment all require thin section bearings, due to the space limitations in these applications.

As the name suggest, thin section bearings are bearings where the space between the inside and outside rings has been reduced. Thin section ball bearings were developed for applications in which space is limited. These include bearings for instrumentation, robotics, medical, aerospace and optical equipment.

Alongside minimal space, thin section bearings can offer a solution when weight reduction is required. This is particularly advantageous for applications that require high levels of precision and accuracy.

Both oils and greases have their advantages and we’ll forgive you for using the terms interchangeably. Technically though, grease is defined as an oil mixed with a thickener. Because of this, oils tend to provide higher running speeds, but will not stay in place as effectively. Therefore, continuous re-application may be needed whether the bearing is sealed or not.For many applications, grease is more convenient as it stays inside the bearing for longer. It benefits from both the properties of the base oil and the added thickener; both having positive effects on the performance of the bearing and its lifespan.

When choosing between oils or greases, it’s important to remember frictional torque levels for a greased bearing are briefly higher to start with, as the bearing begins to spin from stationary. This is because thicker grease takes a short time to ‘run in’ and get distributed inside the bearing. It’s most likely not a problem for many continuous applications, but this could cause problems for stop start equipment.

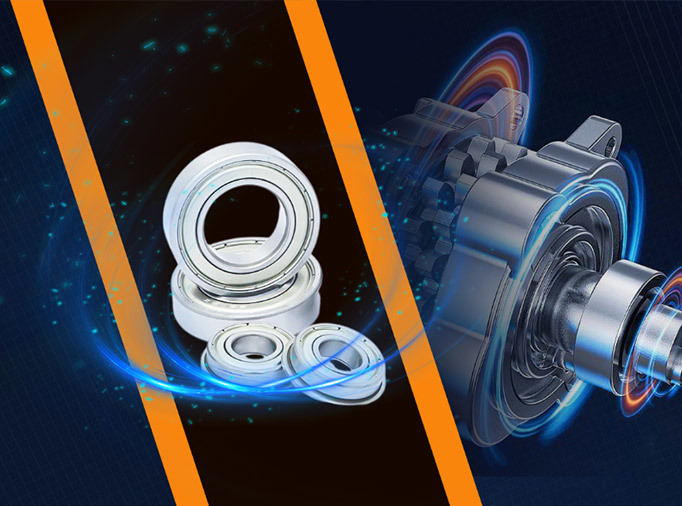

Thrust bearings should not be subjected to a radial load. They are designed for thrust/axial loads only. A standard thrust bearing is comprised of a brass or steel washer containing the balls sandwiched between two other washers which usually have raceways (ball tracks).

Bearings with a flange on the outer ring are easier to mount in a housing then standard bearings as there is much less reliance on the housing tolerance to hold the bearing securely. The flange helps to prevent the bearing from moving in an axial direction when exposed to axial loads or vibration.

The temperature limit for bearings depends on the material of rings and balls, the retainer (cage), any closures such as rubber seals and finally, the lubricant. Chrome steel can support the same loads up to 120°C constant and 150°C intermittent. Above that, the load capacity drops noticeably. For 440 grade stainless steel, the figures are 250°C constant and 300°C intermittent.

The best way to get an exact replacement is to give us the full part number on the invoice or despatch note that came with the original bearing. It is quite likely that you no longer have the paperwork. In that case, measure the bearing: the bore (internal diameter), the OD (outer diameter) and the width. Is the bearing open or does it have metal shields or rubber seals?Identify any other features of the bearing. Does it have a flange on the outer ring? Is the inner ring the same width as the outer ring or wider? Can you see the retainer? If so, is it a steel retainer or made of a different material?

The fuller the description, the better. Is there a reference marked on the bearing? The reference may indicate the bearing material such as chrome steel or stainless steel and possibly confirm any other features such as the tolerance grade or the radial play.

If you are still not sure, send to the bearing to us although without the original reference, we may not be able to confirm tolerance grade, radial play or lubricant.