All You Need to Know About Micro Bearings in the Industrial Equipment and Components - Bearings - Plain Bearings Sector

Time:

2024-01-31

Title: Mastering the Role of Micro Bearings in Industrial Equipment and Components

Introduction:

In the world of industrial equipment and components, bearings play a crucial role in ensuring smooth and efficient machinery operations. Among the various types of bearings, micro bearings find their significance in the realm of plain bearings. This article delves into the practical aspects of micro bearings, offering profound insights into their applications and advantages. With a commitment to providing valuable information, devoid of any pricing or brand affiliations, this article is tailored for professionals seeking to enhance their understanding of the micro bearing domain.

Content:

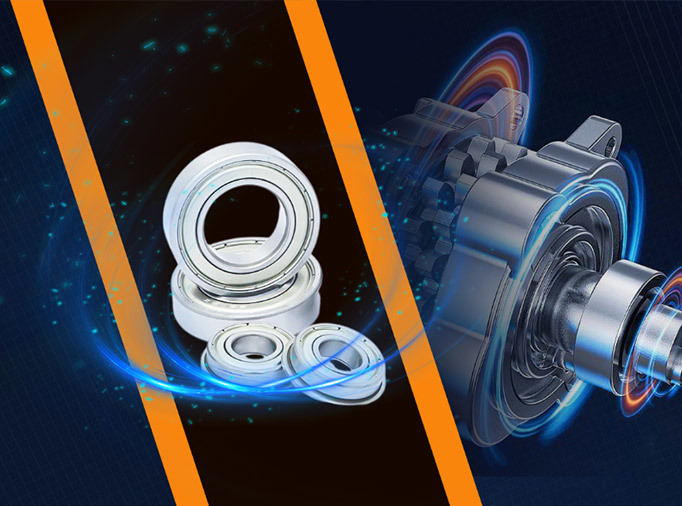

Micro bearings, as the name suggests, are miniature-sized bearings used in a wide range of industrial applications. Specifically, micro bearings find their place in the field of plain bearings, where their compact size and exceptional performance make them indispensable components. These bearings are designed to facilitate smooth sliding motion between two surfaces, reducing friction and enhancing overall machinery efficiency.

One of the key advantages of micro bearings is their ability to operate in high-speed and high-load conditions. With their precision engineering and advanced materials, micro bearings can withstand heavy-duty applications without compromising on performance. This makes them ideal for use in industries such as aerospace, automotive, medical devices, and precision instruments, where reliability and durability are paramount.

Micro bearings are commonly utilized in various machinery and equipment, including micro motors, computer hard drives, printers, scanners, and optical devices. They are also extensively employed in linear motion systems, where they enable precise movements in manufacturing and production lines. Additionally, micro bearings have found their way into consumer electronics, such as smartphones and gaming consoles, contributing to their smooth operation.

When it comes to the design and construction of micro bearings, manufacturers employ advanced techniques and materials to ensure optimal performance. These bearings are typically made from high-quality stainless steel, ceramics, or even hybrid materials, combining the strengths of different materials to achieve superior results. The precision in the manufacturing process guarantees tight tolerances and accurate dimensions, allowing for seamless integration into various applications.

In conclusion, micro bearings are vital components in the field of industrial equipment and components, specifically in the realm of plain bearings. Their compact size, high-speed capabilities, and exceptional performance make them indispensable in numerous applications. Whether it is enabling smooth sliding motion, reducing friction, or ensuring precise movements, micro bearings play a crucial role in enhancing overall machinery efficiency. By understanding the practical aspects and advantages of micro bearings, professionals in this industry can make informed decisions when it comes to selecting and utilizing these essential components.

Related recommend

Share