Optimizing Operations with Deep Groove Ball Bearings: A Comprehensive Guide

Time:

2025-03-04

Optimizing Operations with Deep Groove Ball Bearings

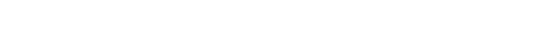

In the realm of industrial equipment and components, **deep groove ball bearings** play a pivotal role in ensuring operational efficiency and reliability. As a fundamental component in various machinery, these bearings facilitate smooth rotational movements while supporting radial and axial loads. In this article, we explore the various aspects of deep groove ball bearings, how they optimize operations, and the best practices for selection and maintenance.

Table of Contents

- Understanding Deep Groove Ball Bearings

- Benefits of Using Deep Groove Ball Bearings

- Applications in Various Industries

- How to Select the Right Deep Groove Ball Bearing

- Installation Best Practices for Deep Groove Ball Bearings

- Maintenance and Care for Longevity

- Troubleshooting Common Issues with Deep Groove Ball Bearings

- Conclusion

- FAQs

Understanding Deep Groove Ball Bearings

Deep groove ball bearings are characterized by their deep raceway grooves that facilitate high-speed operation and accommodate both radial and axial loads. These bearings consist of an inner and outer ring, a cage, and rolling elements (balls) that reduce friction and wear as they rotate. With a simple design, deep groove ball bearings provide exceptional performance across a wide range of applications, making them one of the most commonly used types of bearings in various industries.

Key Features of Deep Groove Ball Bearings

Some notable features of deep groove ball bearings include:

- Versatility: Suitable for both radial and axial loads.

- High Rotational Speeds: Designed to operate efficiently at high speeds.

- Low Friction: Enhanced design minimizes friction and increases lifespan.

- Ease of Maintenance: Simple to install and maintain, reducing downtime.

Benefits of Using Deep Groove Ball Bearings

The adoption of deep groove ball bearings in industrial operations offers several advantages that can lead to improved productivity and efficiency:

1. Enhanced Efficiency

Deep groove ball bearings are designed for high-speed operations, which enhances the overall efficiency of machinery. The reduction in friction leads to less energy consumption, ultimately resulting in cost savings.

2. Increased Load Capacity

These bearings can handle both axial and radial loads, allowing for a more compact design in machinery without sacrificing performance. This feature is especially beneficial in applications where space is limited.

3. Improved Durability

With proper lubrication and maintenance, deep groove ball bearings can operate effectively for extended periods. Their design reduces wear, leading to a longer operational lifespan and lower replacement costs.

4. Versatile Applications

From automotive to manufacturing, deep groove ball bearings are widely used across multiple industries. Their versatility makes them suitable for various machinery, including electric motors, pumps, and conveyors.

Applications in Various Industries

Deep groove ball bearings find applications in multiple sectors due to their reliability and efficiency. Here are some key industries where they are commonly used:

1. Automotive Industry

In vehicles, deep groove ball bearings are employed in wheel hubs, transmissions, and engine components, ensuring smooth operation and longevity.

2. Manufacturing Sector

In manufacturing plants, these bearings are integral to conveyor systems, robotic arms, and production machinery, enabling seamless operations.

3. Aerospace Industry

Aerospace components require high-precision bearings that can withstand extreme conditions. Deep groove ball bearings are used in landing gear, engines, and control systems.

4. Electric Motors

Electric motors rely on deep groove ball bearings for efficient performance, stability, and minimal noise levels, making them essential in HVAC systems, industrial machinery, and household appliances.

How to Select the Right Deep Groove Ball Bearing

Selecting the appropriate deep groove ball bearing for your application involves considering several critical factors:

1. Load Requirements

Determine the type and magnitude of loads (radial, axial, or both) that the bearing will support. This will influence the size and design of the bearing required.

2. Speed Ratings

Bearings are rated for maximum speed; select one that can handle the operational speed of your machinery without compromising performance.

3. Environmental Conditions

Consider the operating environment, including temperature extremes, moisture, and exposure to contaminants. Choose bearings with appropriate sealing solutions if necessary.

4. Material Selection

Bearings come in various materials, including steel and ceramic. The choice of material affects durability, resistance to wear, and overall performance.

Installation Best Practices for Deep Groove Ball Bearings

Proper installation is crucial for the optimal performance of deep groove ball bearings. Here are some best practices to consider:

1. Cleanliness is Key

Before installation, ensure that all components are clean and free from debris, dirt, and contaminants to prevent premature wear.

2. Use Proper Tools

Utilize the correct tools to avoid damaging the bearings during installation. A bearing press or dedicated installation tools can help in achieving proper alignment.

3. Follow Manufacturer Guidelines

Always refer to the manufacturer's guidelines for specific installation procedures, including torque specifications and lubrication requirements.

Maintenance and Care for Longevity

To ensure the longevity and performance of deep groove ball bearings, regular maintenance is essential. Here are some tips:

1. Regular Lubrication

Ensure that bearings are adequately lubricated according to the manufacturer's recommendations. Proper lubrication minimizes friction and wear.

2. Monitor Operational Conditions

Keep an eye on operating conditions, including temperature and vibration levels. Any significant deviations could indicate potential issues.

3. Conduct Routine Inspections

Regular inspections can help identify wear or damage early, allowing for timely repairs or replacements and preventing costly downtimes.

Troubleshooting Common Issues with Deep Groove Ball Bearings

Even with proper maintenance, issues can arise with deep groove ball bearings. Here are some common problems and their solutions:

1. Excessive Noise

If bearings produce unusual noise, it could indicate misalignment, lack of lubrication, or wear. Inspect and address these issues immediately.

2. Overheating

Overheating can result from inadequate lubrication, excessive load, or contamination. Evaluate and rectify the cause to prevent damage.

3. Vibration

Excessive vibration can signal misalignment or wear. Regularly check alignment and inspect for any signs of damage.

Conclusion

Deep groove ball bearings are integral to optimizing operations across numerous industries. Their ability to handle both radial and axial loads efficiently makes them a preferred choice for manufacturers worldwide. By understanding their features, benefits, and maintenance requirements, businesses can enhance their machinery's performance and longevity. Investing time in proper selection, installation, and maintenance practices will yield significant returns in operational efficiency and reduced downtimes.

FAQs

1. What are deep groove ball bearings used for?

Deep groove ball bearings are used in various applications, including automotive, manufacturing, and aerospace industries, for supporting rotating shafts and reducing friction.

2. How do I know when to replace my deep groove ball bearings?

Signs of wear, such as excessive noise, overheating, or vibration, indicate that it may be time to replace your bearings.

3. Can deep groove ball bearings be lubricated?

Yes, lubrication is essential for deep groove ball bearings to minimize friction and wear; be sure to follow the manufacturer's lubrication guidelines.

4. Are deep groove ball bearings suitable for high-speed applications?

Yes, deep groove ball bearings are designed for high-speed operations, making them ideal for applications requiring efficient performance.

5. How long do deep groove ball bearings typically last?

The lifespan of deep groove ball bearings varies based on application, load, and maintenance, but with proper care, they can last for several years.

Related recommend

Share