The Advantages of Using Micro Bearings in Sliding Bearing Systems

Time:

2024-05-05

# Introduction

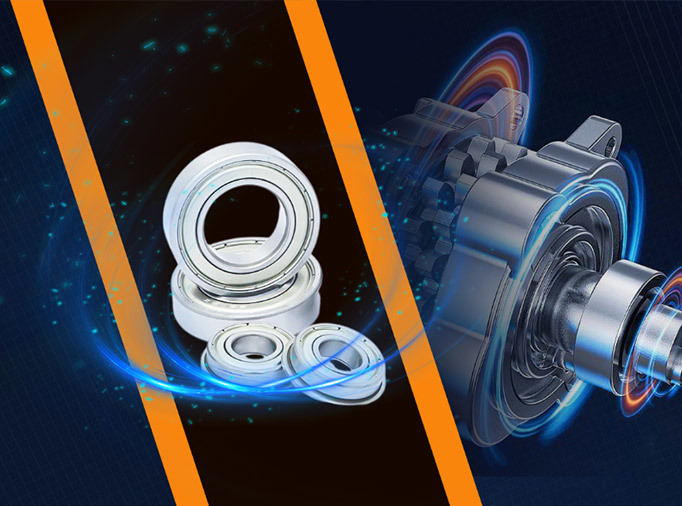

Micro bearings are small but mighty components that play a crucial role in the functionality of sliding bearing systems. In this article, we will explore the advantages of using micro bearings in industrial equipment, highlighting their impact on performance and efficiency.

## What are Micro Bearings?

Micro bearings are miniature ball bearings designed to handle high speeds and precise applications. These small components are made with precision engineering to ensure smooth rotation and minimal friction in sliding bearing systems.

## Advantages of Micro Bearings

### 1. Size and Weight

Micro bearings are compact and lightweight, making them ideal for applications where space is limited. Their small size allows for greater design flexibility and integration into tight spaces within industrial equipment.

### 2. Precision and Accuracy

Micro bearings are manufactured with high precision and accuracy, resulting in smooth and efficient operation. Their tight tolerances ensure minimal vibration and noise, enhancing the overall performance of sliding bearing systems.

### 3. Durability and Longevity

Despite their small size, micro bearings are built to withstand heavy loads and harsh operating conditions. With proper maintenance, these components can provide long-lasting performance and reliability in industrial applications.

### 4. Efficiency and Energy Savings

The use of micro bearings in sliding bearing systems can improve efficiency by reducing friction and energy consumption. Their smooth operation minimizes wear and tear, resulting in lower maintenance costs and extended equipment lifespan.

### 5. Versatility and Adaptability

Micro bearings are versatile components that can be customized to meet specific application requirements. With a wide range of sizes and configurations available, these bearings can be tailored to fit various industrial equipment and machinery.

# FAQs

## Q: Are micro bearings suitable for high-speed applications?

A: Yes, micro bearings are designed to handle high speeds and precise movements, making them ideal for a wide range of industrial applications.

## Q: How long do micro bearings last?

A: With proper maintenance and lubrication, micro bearings can provide reliable performance for an extended period, contributing to the longevity of sliding bearing systems.

## Q: Can micro bearings reduce energy consumption?

A: Yes, the use of micro bearings in sliding bearing systems can improve efficiency and reduce energy consumption due to their low friction and smooth operation.

## Q: Are micro bearings cost-effective?

A: Despite their precision engineering and durability, micro bearings are cost-effective solutions for industrial equipment due to their long-lasting performance and reliability.

## Q: How can I customize micro bearings for my specific application?

A: Micro bearings come in a variety of sizes and configurations, allowing for easy customization to meet the unique requirements of different industrial equipment and machinery.

# Conclusion

In conclusion, the advantages of using micro bearings in sliding bearing systems are undeniable. From their compact size and precision engineering to their durability and efficiency, these small components offer significant benefits for industrial equipment. By incorporating micro bearings into your sliding bearing systems, you can enhance performance, reduce maintenance costs, and improve overall reliability. Consider the advantages of micro bearings when designing or upgrading your industrial equipment for optimal functionality and longevity.

Micro bearings are small but mighty components that play a crucial role in the functionality of sliding bearing systems. In this article, we will explore the advantages of using micro bearings in industrial equipment, highlighting their impact on performance and efficiency.

## What are Micro Bearings?

Micro bearings are miniature ball bearings designed to handle high speeds and precise applications. These small components are made with precision engineering to ensure smooth rotation and minimal friction in sliding bearing systems.

## Advantages of Micro Bearings

### 1. Size and Weight

Micro bearings are compact and lightweight, making them ideal for applications where space is limited. Their small size allows for greater design flexibility and integration into tight spaces within industrial equipment.

### 2. Precision and Accuracy

Micro bearings are manufactured with high precision and accuracy, resulting in smooth and efficient operation. Their tight tolerances ensure minimal vibration and noise, enhancing the overall performance of sliding bearing systems.

### 3. Durability and Longevity

Despite their small size, micro bearings are built to withstand heavy loads and harsh operating conditions. With proper maintenance, these components can provide long-lasting performance and reliability in industrial applications.

### 4. Efficiency and Energy Savings

The use of micro bearings in sliding bearing systems can improve efficiency by reducing friction and energy consumption. Their smooth operation minimizes wear and tear, resulting in lower maintenance costs and extended equipment lifespan.

### 5. Versatility and Adaptability

Micro bearings are versatile components that can be customized to meet specific application requirements. With a wide range of sizes and configurations available, these bearings can be tailored to fit various industrial equipment and machinery.

# FAQs

## Q: Are micro bearings suitable for high-speed applications?

A: Yes, micro bearings are designed to handle high speeds and precise movements, making them ideal for a wide range of industrial applications.

## Q: How long do micro bearings last?

A: With proper maintenance and lubrication, micro bearings can provide reliable performance for an extended period, contributing to the longevity of sliding bearing systems.

## Q: Can micro bearings reduce energy consumption?

A: Yes, the use of micro bearings in sliding bearing systems can improve efficiency and reduce energy consumption due to their low friction and smooth operation.

## Q: Are micro bearings cost-effective?

A: Despite their precision engineering and durability, micro bearings are cost-effective solutions for industrial equipment due to their long-lasting performance and reliability.

## Q: How can I customize micro bearings for my specific application?

A: Micro bearings come in a variety of sizes and configurations, allowing for easy customization to meet the unique requirements of different industrial equipment and machinery.

# Conclusion

In conclusion, the advantages of using micro bearings in sliding bearing systems are undeniable. From their compact size and precision engineering to their durability and efficiency, these small components offer significant benefits for industrial equipment. By incorporating micro bearings into your sliding bearing systems, you can enhance performance, reduce maintenance costs, and improve overall reliability. Consider the advantages of micro bearings when designing or upgrading your industrial equipment for optimal functionality and longevity.

Related recommend

Share