The Ultimate Guide to Micro Bearings in Industrial Equipment

Time:

2024-05-07

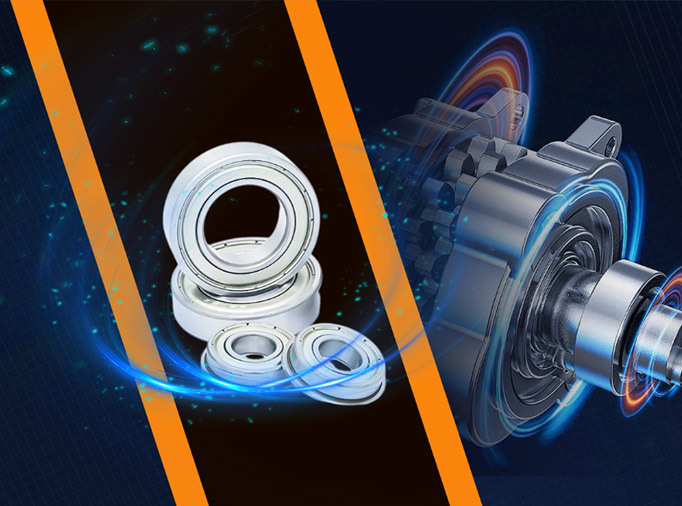

Micro bearings play a crucial role in the functioning of industrial equipment, especially in the realm of sliding bearings. These miniature components are designed to provide smooth and precise motion control, making them essential in various applications within the industrial sector.

One of the key features of micro bearings is their compact size, which allows for installation in tight spaces without compromising performance. Despite their small dimensions, micro bearings offer high load-carrying capacity and durability, ensuring reliable operation even in demanding conditions.

In industrial equipment, micro bearings are commonly used in the automotive, aerospace, and manufacturing industries. They are employed in applications such as conveyor systems, robotics, and precision machinery, where precise motion control is essential for optimal performance.

Micro bearings offer several benefits in industrial equipment, including reduced friction, noise, and maintenance requirements. Their high precision and low wear characteristics contribute to improved efficiency and longevity of machinery, ultimately leading to cost savings for businesses.

When selecting micro bearings for industrial equipment, it is important to consider factors such as load capacity, speed, operating environment, and lubrication requirements. Proper installation, maintenance, and monitoring of micro bearings are also critical to ensure optimal performance and longevity.

In conclusion, micro bearings are indispensable components in the world of industrial equipment, particularly in the realm of sliding bearings. By understanding their key features, applications, and benefits, businesses can harness the power of micro bearings to enhance the performance and efficiency of their machinery.

One of the key features of micro bearings is their compact size, which allows for installation in tight spaces without compromising performance. Despite their small dimensions, micro bearings offer high load-carrying capacity and durability, ensuring reliable operation even in demanding conditions.

In industrial equipment, micro bearings are commonly used in the automotive, aerospace, and manufacturing industries. They are employed in applications such as conveyor systems, robotics, and precision machinery, where precise motion control is essential for optimal performance.

Micro bearings offer several benefits in industrial equipment, including reduced friction, noise, and maintenance requirements. Their high precision and low wear characteristics contribute to improved efficiency and longevity of machinery, ultimately leading to cost savings for businesses.

When selecting micro bearings for industrial equipment, it is important to consider factors such as load capacity, speed, operating environment, and lubrication requirements. Proper installation, maintenance, and monitoring of micro bearings are also critical to ensure optimal performance and longevity.

In conclusion, micro bearings are indispensable components in the world of industrial equipment, particularly in the realm of sliding bearings. By understanding their key features, applications, and benefits, businesses can harness the power of micro bearings to enhance the performance and efficiency of their machinery.

Share