Everything You Need to Know About Ball Bearings in Industrial Equipment

Time:

2024-05-31

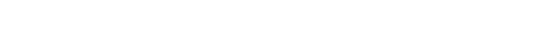

Ball bearings play a crucial role in the smooth operation of industrial equipment, especially in the category of "Other Bearings." These precision-engineered components are designed to reduce friction and support rotational motion, ensuring efficiency and reliability in a wide range of applications.

One of the key advantages of ball bearings is their ability to handle both radial and thrust loads, making them versatile solutions for various types of machinery and equipment. The design of ball bearings consists of balls sandwiched between two rings, known as the inner and outer races, which are engineered to minimize friction and maximize performance.

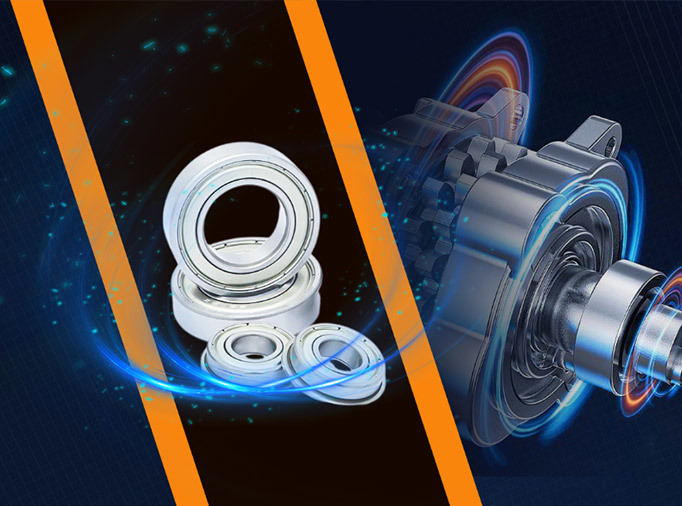

In industrial equipment, ball bearings are commonly used in applications such as motors, pumps, compressors, and gearboxes, where smooth and efficient operation is essential. By incorporating high-quality ball bearings into these components, manufacturers can improve overall performance, extend equipment lifespan, and reduce maintenance requirements.

When selecting ball bearings for industrial equipment, factors such as load capacity, speed ratings, and operating conditions must be carefully considered to ensure optimal performance and longevity. Additionally, proper installation, lubrication, and maintenance are critical to maximizing the service life of ball bearings and preventing premature failure.

In conclusion, ball bearings are indispensable components in industrial equipment and play a vital role in ensuring smooth and reliable operation. By understanding the fundamentals of ball bearings and their applications in the category of "Other Bearings," professionals in the industry can make informed decisions when selecting and maintaining these essential components.

One of the key advantages of ball bearings is their ability to handle both radial and thrust loads, making them versatile solutions for various types of machinery and equipment. The design of ball bearings consists of balls sandwiched between two rings, known as the inner and outer races, which are engineered to minimize friction and maximize performance.

In industrial equipment, ball bearings are commonly used in applications such as motors, pumps, compressors, and gearboxes, where smooth and efficient operation is essential. By incorporating high-quality ball bearings into these components, manufacturers can improve overall performance, extend equipment lifespan, and reduce maintenance requirements.

When selecting ball bearings for industrial equipment, factors such as load capacity, speed ratings, and operating conditions must be carefully considered to ensure optimal performance and longevity. Additionally, proper installation, lubrication, and maintenance are critical to maximizing the service life of ball bearings and preventing premature failure.

In conclusion, ball bearings are indispensable components in industrial equipment and play a vital role in ensuring smooth and reliable operation. By understanding the fundamentals of ball bearings and their applications in the category of "Other Bearings," professionals in the industry can make informed decisions when selecting and maintaining these essential components.

Related recommend

Share