Demystifying the Inner Workings of Roller Bearings: A Comprehensive Guide

Time:

2024-11-09

Demystifying the Inner Workings of Roller Bearings

Table of Contents

1. Introduction to Roller Bearings

2. The Fundamental Design of Roller Bearings

2.1 Key Components of Roller Bearings

2.2 Types of Roller Bearings Explained

3. How Roller Bearings Work

3.1 Load Distribution and Support

3.2 Friction Reduction Mechanism

4. Applications of Roller Bearings in Various Industries

4.1 Roller Bearings in Automotive Sector

4.2 Industrial Machinery and Equipment

5. Maintenance and Care for Roller Bearings

5.1 Common Issues and Symptoms

5.2 Best Practices for Longevity

6. Future Innovations in Roller Bearing Technology

7. FAQs about Roller Bearings

8. Conclusion

1. Introduction to Roller Bearings

Roller bearings play a vital role in modern machinery, ensuring smooth and efficient movement in countless applications across various industries. Understanding their inner workings is crucial for engineers, manufacturers, and technicians involved in design and maintenance. This article delves deeply into roller bearings, shedding light on their construction, operational principles, applications, and maintenance.

2. The Fundamental Design of Roller Bearings

Roller bearings consist of several essential components that work together to reduce friction and support mechanical loads.

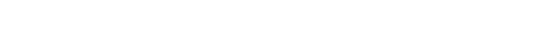

2.1 Key Components of Roller Bearings

At the core of every roller bearing are the **inner race**, **outer race**, and **rolling elements**. The inner and outer races serve as tracks for the rolling elements, which can be cylindrical, spherical, or tapered, depending on the type of bearing. Additionally, **cages** are often included to separate the rolling elements, allowing for smoother movement and reducing wear over time.

2.2 Types of Roller Bearings Explained

There are several types of roller bearings, each designed to handle specific loads and applications:

- **Cylindrical Roller Bearings**: These bearings use cylindrical rolling elements and are ideal for high radial loads.

- **Spherical Roller Bearings**: Designed to accommodate misalignment, these bearings have spherical rolling elements and can handle both radial and axial loads.

- **Tapered Roller Bearings**: With conical rolling elements, these bearings are used in applications requiring high axial load capacity along with radial strength.

- **Needle Bearings**: Featuring long, thin cylindrical rollers, needle bearings are excellent for limited spaces where high load capacity is required.

3. How Roller Bearings Work

Understanding how roller bearings function is essential for appreciating their significance in machinery.

3.1 Load Distribution and Support

Roller bearings distribute loads across a larger surface area than traditional ball bearings. This characteristic allows them to support heavier loads while maintaining lower friction levels, leading to greater efficiency and durability in machinery.

3.2 Friction Reduction Mechanism

The rolling motion of the elements in roller bearings reduces friction compared to sliding contact bearings. This reduction in friction results in less heat generation, extending the lifespan of both the bearing and the equipment it supports.

4. Applications of Roller Bearings in Various Industries

Roller bearings are utilized in various sectors, showcasing their versatility and importance.

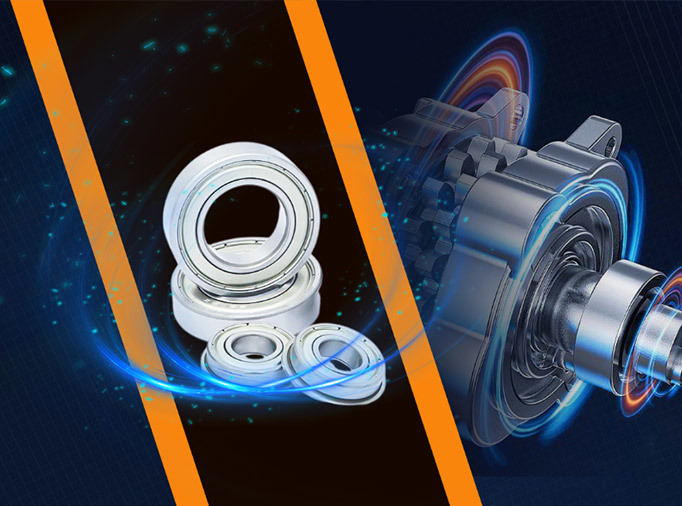

4.1 Roller Bearings in Automotive Sector

In the automotive industry, roller bearings are crucial components in wheel assemblies, transmissions, and engine systems. They enhance vehicle performance by improving fuel efficiency and reducing wear on parts.

4.2 Industrial Machinery and Equipment

Industrial machinery relies heavily on roller bearings for operational efficiency. They are used in conveyor systems, pumps, and manufacturing equipment, providing reliable support for heavy loads and reducing downtime due to wear and tear.

5. Maintenance and Care for Roller Bearings

Proper maintenance of roller bearings is essential to ensure their longevity and performance.

5.1 Common Issues and Symptoms

Some common problems associated with roller bearings include overheating, excessive noise, and visible wear on the races and rolling elements. Addressing these issues promptly is vital to prevent further damage.

5.2 Best Practices for Longevity

Regular inspections, proper lubrication, and ensuring appropriate load conditions are fundamental practices that enhance the lifespan of roller bearings. Implementing a maintenance schedule can help identify potential issues before they escalate.

6. Future Innovations in Roller Bearing Technology

The field of roller bearing technology is continually evolving. Recent advancements include the use of advanced materials, such as ceramics and composites, which can offer improved performance under extreme conditions. Additionally, the integration of smart technologies for monitoring and predictive maintenance is becoming increasingly common.

7. FAQs about Roller Bearings

**Q1: What are the main advantages of using roller bearings?**

A: Roller bearings provide superior load capacity, reduced friction, and longer service life compared to other bearing types.

**Q2: How often should roller bearings be lubricated?**

A: The lubrication frequency depends on the application and operating conditions, but regular inspection is recommended to determine maintenance needs.

**Q3: Can roller bearings function in extreme temperatures?**

A: Yes, specialized roller bearings are designed to operate in extreme temperatures, with materials and lubricants suited for high or low-temperature environments.

**Q4: What happens if roller bearings are overloaded?**

A: Overloading roller bearings can lead to premature wear, overheating, and ultimately bearing failure.

**Q5: How can I tell if my roller bearings need to be replaced?**

A: Signs of wear, such as unusual noise, excessive vibration, or visible damage, indicate that it may be time to replace roller bearings.

8. Conclusion

Roller bearings are indispensable components in the machinery that drives modern industry. Understanding their design, functionality, and maintenance is essential for optimizing performance and ensuring longevity. As technology advances, so too do the capabilities of roller bearings, promising even greater efficiency and reliability in the future. Embracing these innovations will enable industries to enhance productivity while minimizing operating costs. Investing time in understanding and maintaining roller bearings is a step toward achieving operational excellence.

Related recommend

Share