The Essential Guide to Ball Bearings in Industrial Applications

Time:

2025-02-07

Ball bearings are essential components widely used in various industrial applications, serving as a crucial interface between moving parts to reduce friction and wear. They consist of spherical balls encased in a raceway, allowing for smooth rotational movement. The design of ball bearings enables them to support loads while minimizing resistance, making them indispensable in machinery and equipment.

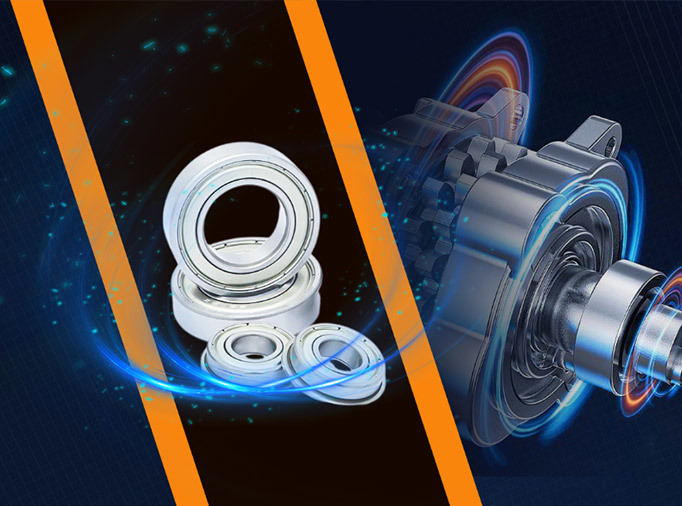

One of the primary advantages of ball bearings is their ability to handle both radial and axial loads. This versatility makes them suitable for a wide range of applications, from electric motors and automotive systems to conveyor systems and industrial machinery. By distributing loads evenly, ball bearings significantly enhance the performance and efficiency of mechanical systems.

When selecting ball bearings for specific applications, it is crucial to consider several factors. The type of bearing required often depends on the load conditions, speed, and environmental factors such as temperature and contamination. For example, deep groove ball bearings are commonly used in high-speed applications, while angular contact ball bearings are ideal for supporting axial loads in one direction.

Proper lubrication is also vital for the longevity and performance of ball bearings. Lubricants reduce friction between the balls and raceways, preventing overheating and wear. Different types of lubricants, such as grease or oil, can be used depending on the operating conditions. Ensuring that ball bearings are adequately lubricated can extend their lifespan and maintain operational efficiency.

Another important consideration when working with ball bearings is the installation process. Proper installation techniques are essential to avoid premature failure. Misalignment, excessive force during installation, or contamination can lead to significant issues. It is advisable to follow manufacturer guidelines for installation and maintenance to ensure optimal performance.

In conclusion, ball bearings are integral to the efficiency and functionality of industrial equipment. Understanding their design, selection criteria, and maintenance practices can help manufacturers and engineers optimize their systems. By choosing the right ball bearings and implementing best practices, you can enhance the performance and durability of your machinery, ultimately leading to increased productivity and reduced operational costs. Investing time and resources into understanding ball bearings will yield significant benefits in your industrial applications.

One of the primary advantages of ball bearings is their ability to handle both radial and axial loads. This versatility makes them suitable for a wide range of applications, from electric motors and automotive systems to conveyor systems and industrial machinery. By distributing loads evenly, ball bearings significantly enhance the performance and efficiency of mechanical systems.

When selecting ball bearings for specific applications, it is crucial to consider several factors. The type of bearing required often depends on the load conditions, speed, and environmental factors such as temperature and contamination. For example, deep groove ball bearings are commonly used in high-speed applications, while angular contact ball bearings are ideal for supporting axial loads in one direction.

Proper lubrication is also vital for the longevity and performance of ball bearings. Lubricants reduce friction between the balls and raceways, preventing overheating and wear. Different types of lubricants, such as grease or oil, can be used depending on the operating conditions. Ensuring that ball bearings are adequately lubricated can extend their lifespan and maintain operational efficiency.

Another important consideration when working with ball bearings is the installation process. Proper installation techniques are essential to avoid premature failure. Misalignment, excessive force during installation, or contamination can lead to significant issues. It is advisable to follow manufacturer guidelines for installation and maintenance to ensure optimal performance.

In conclusion, ball bearings are integral to the efficiency and functionality of industrial equipment. Understanding their design, selection criteria, and maintenance practices can help manufacturers and engineers optimize their systems. By choosing the right ball bearings and implementing best practices, you can enhance the performance and durability of your machinery, ultimately leading to increased productivity and reduced operational costs. Investing time and resources into understanding ball bearings will yield significant benefits in your industrial applications.

Related recommend

Share