Understanding Ball Bearings: Key Insights for Industrial Applications

Time:

2025-02-17

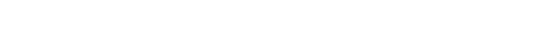

Ball bearings are essential components in various industrial applications, serving a critical function in reducing friction and facilitating smooth rotational or linear movement within machinery. These devices consist of spherical balls that are placed between two smooth surfaces, allowing for low-friction motion. Understanding ball bearings is vital for professionals involved in the manufacturing, maintenance, or design of industrial equipment.

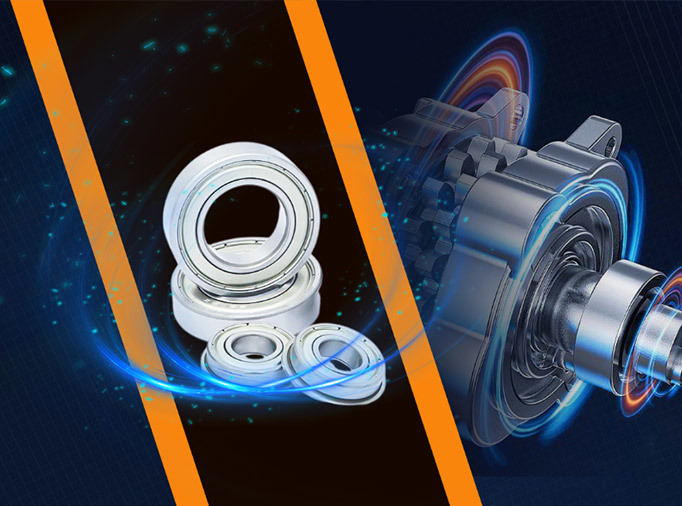

One of the primary advantages of ball bearings is their ability to handle both radial and axial loads, making them versatile for diverse applications. They are commonly used in electric motors, conveyor systems, and automotive components. When selecting the appropriate ball bearing for a specific application, several factors should be considered. These include load capacity, speed rating, operating temperature, and environmental conditions. It is essential to assess these criteria to ensure optimal performance and longevity of the equipment.

Another critical aspect is the material composition of ball bearings. Typically, they are made from high-carbon chrome steel, stainless steel, or ceramic materials. Each material offers distinct benefits; for instance, ceramic bearings possess excellent corrosion resistance and are lightweight, making them suitable for high-speed applications. Conversely, steel bearings are more robust and can handle higher loads but may require regular lubrication to reduce wear and tear.

Proper maintenance is crucial to prolonging the life of ball bearings. Regular inspection and lubrication can prevent premature failure and ensure smooth operation. Choosing the right lubricant is also essential; it should be compatible with the bearing material and the operational environment. Factors such as temperature, humidity, and contamination levels should be taken into account when determining the lubrication type and interval.

Installation also plays a significant role in the performance of ball bearings. It is crucial to follow the manufacturer's guidelines to avoid misalignment and ensure that the bearings are seated correctly. Proper alignment minimizes stress on the bearing surfaces, reducing the risk of premature wear.

In recent years, advancements in technology have led to the development of specialized ball bearings designed for specific applications, such as those operating in extreme temperatures or environments with high levels of contamination. Understanding the various types of ball bearings available can help organizations make informed decisions that enhance the efficiency and reliability of their machinery.

In conclusion, ball bearings are fundamental to the performance and longevity of industrial equipment. By comprehensively understanding their design, materials, maintenance needs, and installation requirements, professionals can optimize their use in various applications. Staying informed about advancements in bearing technology will also provide a competitive edge in the industrial sector.

One of the primary advantages of ball bearings is their ability to handle both radial and axial loads, making them versatile for diverse applications. They are commonly used in electric motors, conveyor systems, and automotive components. When selecting the appropriate ball bearing for a specific application, several factors should be considered. These include load capacity, speed rating, operating temperature, and environmental conditions. It is essential to assess these criteria to ensure optimal performance and longevity of the equipment.

Another critical aspect is the material composition of ball bearings. Typically, they are made from high-carbon chrome steel, stainless steel, or ceramic materials. Each material offers distinct benefits; for instance, ceramic bearings possess excellent corrosion resistance and are lightweight, making them suitable for high-speed applications. Conversely, steel bearings are more robust and can handle higher loads but may require regular lubrication to reduce wear and tear.

Proper maintenance is crucial to prolonging the life of ball bearings. Regular inspection and lubrication can prevent premature failure and ensure smooth operation. Choosing the right lubricant is also essential; it should be compatible with the bearing material and the operational environment. Factors such as temperature, humidity, and contamination levels should be taken into account when determining the lubrication type and interval.

Installation also plays a significant role in the performance of ball bearings. It is crucial to follow the manufacturer's guidelines to avoid misalignment and ensure that the bearings are seated correctly. Proper alignment minimizes stress on the bearing surfaces, reducing the risk of premature wear.

In recent years, advancements in technology have led to the development of specialized ball bearings designed for specific applications, such as those operating in extreme temperatures or environments with high levels of contamination. Understanding the various types of ball bearings available can help organizations make informed decisions that enhance the efficiency and reliability of their machinery.

In conclusion, ball bearings are fundamental to the performance and longevity of industrial equipment. By comprehensively understanding their design, materials, maintenance needs, and installation requirements, professionals can optimize their use in various applications. Staying informed about advancements in bearing technology will also provide a competitive edge in the industrial sector.

Related recommend

Share