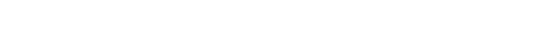

Deep Groove Ball Bearing: A Crucial Component in Industrial Equipment and Machinery

Time:

2023-08-05

Introduction:

Deep groove ball bearings are an essential part of the industrial equipment and components industry, particularly in the field of bearings. These versatile components play a crucial role in ensuring the smooth and efficient operation of machinery and equipment across a wide range of applications. In this article, we will explore the significance of deep groove ball bearings in the industrial sector and their vital contributions to the reliability and performance of various equipment.

1. Understanding Deep Groove Ball Bearings:

Deep groove ball bearings are a type of rolling-element bearing that consists of an inner ring, an outer ring, a series of balls, and a cage. This design allows the bearings to accommodate radial as well as axial loads in both directions, making them suitable for a wide range of applications. The deep groove design enables these bearings to withstand high speeds and operate with minimal friction, resulting in enhanced efficiency and reduced energy consumption.

2. Versatility and Applications:

Deep groove ball bearings find applications in various industrial equipment and components, including but not limited to:

- Electric motors: These bearings support the smooth rotation of motor shafts and contribute to the overall efficiency and reliability of electric motors in machinery and appliances.

- Automotive industry: They are extensively used in vehicles, ensuring the smooth operation of components such as alternators, starters, water pumps, and air conditioning systems.

- Industrial machinery: Deep groove ball bearings are crucial components in various types of machinery, such as pumps, gearboxes, conveyors, and power tools, ensuring their reliable and efficient performance.

- Agricultural equipment: In farming machinery like tractors and harvesters, deep groove ball bearings help in facilitating smooth movement and reducing friction in rotating parts.

- Appliances: From washing machines to refrigerators, deep groove ball bearings play a vital role in ensuring the smooth operation of various household appliances.

3. Advantages of Deep Groove Ball Bearings:

- High speed operation: Deep groove ball bearings are designed to withstand high rotational speeds, making them suitable for applications that require rapid movement or rotation.

- Low noise and vibration: These bearings are engineered to minimize noise and vibration during operation, contributing to a quieter and more comfortable environment in industrial settings.

- Easy installation and maintenance: Deep groove ball bearings are relatively simple to install and require minimal maintenance, reducing downtime and overall operational costs.

- Cost-effective: Their versatility, long service life, and low maintenance requirements make deep groove ball bearings a cost-effective choice for many industrial applications.

Conclusion:

Deep groove ball bearings are a fundamental component in the industrial equipment and components industry, providing reliable and efficient operation across various applications. Their ability to withstand high speeds, accommodate radial and axial loads, and contribute to reduced friction and energy consumption makes them indispensable in ensuring the smooth functioning of machinery and equipment. By understanding the significance of deep groove ball bearings, industries can make informed decisions regarding their selection and utilization, leading to enhanced performance, reduced downtime, and improved productivity.

Related recommend

Share