Revolutionizing the Industrial Equipment Industry: The Impact of Micro Bearings

Time:

2023-08-23

**Table of Contents:**

1. Introduction: The Rise of Micro Bearings

2. Understanding Micro Bearings: What Are They?

3. The Benefits of Micro Bearings in Industrial Equipment

4. Applications of Micro Bearings Across Industries

5. Key Factors to Consider When Choosing Micro Bearings

6. Frequently Asked Questions (FAQs) About Micro Bearings

7. Conclusion: The Future of Micro Bearings in Industry

**Introduction: The Rise of Micro Bearings**

In recent years, the industrial equipment industry has witnessed a significant shift towards the adoption of micro bearings. These miniature wonders have revolutionized the field, offering unparalleled precision, durability, and efficiency. This article explores the remarkable impact of micro bearings in various sectors and delves into the reasons behind their growing popularity.

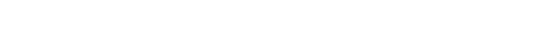

**Understanding Micro Bearings: What Are They?**

Micro bearings, also known as miniature bearings or subminiature bearings, are compact ball bearings designed to withstand high speeds and deliver exceptional performance in small-scale machinery. They are typically less than 22mm in outer diameter and are engineered to operate with minimal friction and noise.

These small but mighty components consist of an outer ring, an inner ring, a cage, and rolling elements such as balls or rollers. They are commonly made of stainless steel or chrome steel, ensuring excellent corrosion resistance and longevity. Micro bearings are often lubricated with grease or oil to reduce friction and enhance their lifespan.

**The Benefits of Micro Bearings in Industrial Equipment**

Micro bearings offer a myriad of advantages that have propelled their widespread adoption in the industrial equipment industry. Some key benefits include:

1. Space Optimization: Due to their compact size, micro bearings enable manufacturers to design and build smaller and more lightweight equipment without sacrificing performance or reliability.

2. High Precision: Micro bearings are engineered to provide precise rotational motion, making them ideal for applications that demand accurate positioning, such as robotics, medical devices, and optical equipment.

3. Low Friction and Energy Efficiency: With their advanced designs and high-quality materials, micro bearings minimize friction, resulting in reduced power consumption and improved energy efficiency.

4. Durability and Longevity: Despite their small size, micro bearings are built to withstand heavy loads, high speeds, and harsh operating conditions, ensuring long-lasting performance and reliability.

5. Quiet Operation: Micro bearings operate with minimal noise, making them suitable for noise-sensitive applications where silence is essential, such as in medical equipment or audio devices.

**Applications of Micro Bearings Across Industries**

Micro bearings find widespread use in various industries, contributing to enhanced efficiency and performance in countless applications. Some notable sectors where micro bearings play a crucial role include:

1. Medical and Healthcare: Micro bearings are vital in medical devices such as surgical instruments, diagnostic equipment, and robotic-assisted surgery systems, where precision and reliability are paramount.

2. Aerospace and Defense: In aerospace applications, micro bearings are used in navigation systems, actuators, control mechanisms, and other critical components that require exceptional precision and durability.

3. Robotics and Automation: Micro bearings enable smooth, accurate, and precise motion control in robotics and automation systems, facilitating tasks ranging from assembly and pick-and-place operations to industrial inspection and testing.

4. Electronics and Semiconductor: Micro bearings are essential in electronic devices, including hard disk drives, printers, scanners, and optical disc drives, supporting rotational motion and ensuring reliable performance.

5. Automotive and Transportation: Micro bearings are found in automotive applications such as electric power steering systems, wiper motors, window regulators, and fuel injection systems, contributing to the overall efficiency and reliability of vehicles.

**Key Factors to Consider When Choosing Micro Bearings**

When selecting micro bearings for industrial equipment, several factors should be taken into account to ensure optimal performance and longevity. These factors include:

1. Load Capacity: Determine the maximum loads that the micro bearings will need to support to ensure they can withstand the forces involved.

2. Speed Rating: Consider the required rotational speeds of the equipment to ensure that the chosen micro bearings can operate safely and efficiently.

3. Precision Requirements: Assess the level of precision needed for the application and choose micro bearings with the appropriate tolerances and accuracy ratings.

4. Environmental Conditions: Consider the operating environment, including temperature, humidity, and exposure to contaminants, to select micro bearings with suitable materials and seals.

5. Lubrication and Maintenance: Evaluate the lubrication requirements and maintenance schedules of the equipment to ensure compatibility with the chosen micro bearings.

**Frequently Asked Questions (FAQs) About Micro Bearings**

1. Q: What distinguishes micro bearings from standard bearings?

A: Micro bearings are smaller in size, designed for high precision and efficiency in small-scale applications.

2. Q: Are micro bearings suitable for high-speed applications?

A: Yes, micro bearings are specifically engineered to withstand high speeds and deliver smooth rotational motion.

3. Q: Can micro bearings handle heavy loads?

A: Despite their small size, micro bearings are designed to handle significant loads and provide reliable performance.

4. Q: What materials are commonly used in micro bearings?

A: Micro bearings are typically made of stainless steel or chrome steel for their durability and corrosion resistance.

5. Q: How do I ensure proper lubrication of micro bearings?

A: Follow the manufacturer's recommendations regarding lubrication type, quantity, and maintenance intervals for optimal performance.

**Conclusion: The Future of Micro Bearings in Industry**

As the industrial equipment industry continues to evolve, micro bearings are poised to play an increasingly pivotal role. Their compact size, exceptional precision, and versatility make them indispensable components in countless applications across various sectors. The unique features and benefits of micro bearings make them a game-changer, enhancing efficiency, performance, and reliability in industrial machinery. Embracing the power of micro bearings opens up new possibilities for innovation and advancement in the industrial equipment industry, paving the way for a future of enhanced productivity and success.

Related recommend

Share