Understanding Ball Bearings: Essential Insights for Industrial Applications

Time:

2024-09-18

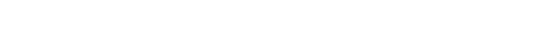

Ball bearings are crucial components in various industrial applications, serving as a fundamental technology enabling smooth and efficient motion in machinery. Their primary purpose is to reduce friction between moving parts, which in turn enhances performance and extends the lifespan of equipment. Understanding the mechanics and advantages of ball bearings can significantly impact operations within the industrial sector.

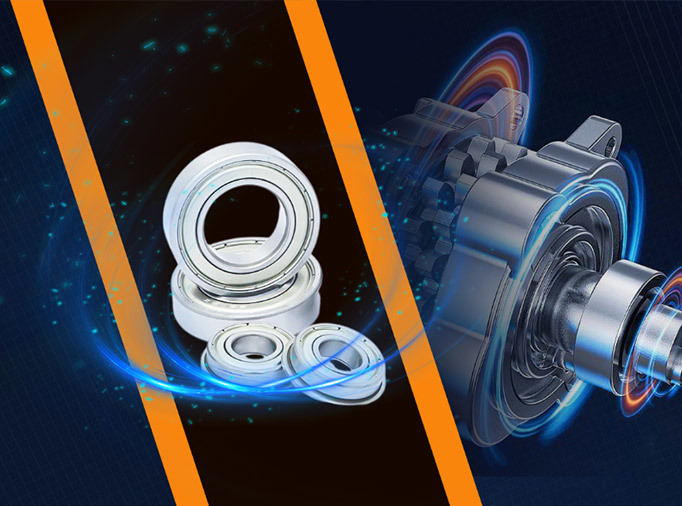

At their core, ball bearings consist of a set of balls held in place between two races: an inner race and an outer race. This design allows for the rotation of the inner race while minimizing friction against the outer race. The balls distribute the load across a larger surface area, which helps to alleviate wear and tear on individual components. This not only leads to improved efficiency but also reduces the likelihood of mechanical failure.

One of the significant advantages of ball bearings is their versatility. They are utilized in a wide range of applications, from electric motors and conveyor systems to automotive components and aerospace equipment. Their ability to accommodate both radial and axial loads makes them suitable for high-speed applications, where traditional sliding bearings may struggle. Additionally, ball bearings are available in various sizes and materials, allowing for customization based on specific operational requirements.

When selecting ball bearings for industrial use, it is essential to consider factors such as load capacity, speed ratings, and the environment in which they will operate. For instance, certain materials may be better suited for high-temperature applications, while others may excel in corrosive environments. Understanding these parameters will ensure optimal performance and longevity of the bearings in your machinery.

Maintenance is also a critical aspect of ensuring the reliability of ball bearings. Regular inspections can help identify wear patterns or lubrication issues before they lead to significant problems. Implementing a proactive maintenance schedule can save time and costs associated with equipment downtime and repairs.

In conclusion, ball bearings play an indispensable role in the efficiency and functionality of industrial equipment. By understanding their design, advantages, and maintenance needs, professionals can make informed decisions that enhance productivity and minimize operational risks. Whether you’re involved in manufacturing, logistics, or machinery maintenance, comprehending the intricacies of ball bearings will undoubtedly contribute to the success of your operations in the industrial landscape.

At their core, ball bearings consist of a set of balls held in place between two races: an inner race and an outer race. This design allows for the rotation of the inner race while minimizing friction against the outer race. The balls distribute the load across a larger surface area, which helps to alleviate wear and tear on individual components. This not only leads to improved efficiency but also reduces the likelihood of mechanical failure.

One of the significant advantages of ball bearings is their versatility. They are utilized in a wide range of applications, from electric motors and conveyor systems to automotive components and aerospace equipment. Their ability to accommodate both radial and axial loads makes them suitable for high-speed applications, where traditional sliding bearings may struggle. Additionally, ball bearings are available in various sizes and materials, allowing for customization based on specific operational requirements.

When selecting ball bearings for industrial use, it is essential to consider factors such as load capacity, speed ratings, and the environment in which they will operate. For instance, certain materials may be better suited for high-temperature applications, while others may excel in corrosive environments. Understanding these parameters will ensure optimal performance and longevity of the bearings in your machinery.

Maintenance is also a critical aspect of ensuring the reliability of ball bearings. Regular inspections can help identify wear patterns or lubrication issues before they lead to significant problems. Implementing a proactive maintenance schedule can save time and costs associated with equipment downtime and repairs.

In conclusion, ball bearings play an indispensable role in the efficiency and functionality of industrial equipment. By understanding their design, advantages, and maintenance needs, professionals can make informed decisions that enhance productivity and minimize operational risks. Whether you’re involved in manufacturing, logistics, or machinery maintenance, comprehending the intricacies of ball bearings will undoubtedly contribute to the success of your operations in the industrial landscape.

Related recommend

Share