The Crucial Impact of Lubrication on the Efficiency and Longevity of Ball Bearings

Time:

2024-09-22

The Crucial Impact of Lubrication on the Efficiency and Longevity of Ball Bearings

Table of Contents

- Introduction to Ball Bearings and Lubrication

- Understanding Lubrication and Its Types

- The Importance of Lubrication in Ball Bearings

- Impact of Lubrication on Bearing Performance

- Best Practices for Lubrication Maintenance

- Common Lubrication Mistakes to Avoid

- Frequently Asked Questions (FAQs)

- Conclusion

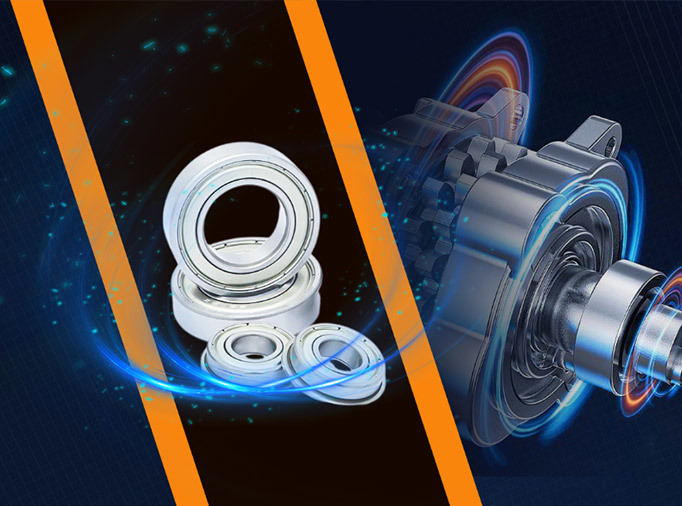

Introduction to Ball Bearings and Lubrication

In the realm of **industrial equipment**, ball bearings play an essential role in ensuring smooth motion and efficiency. These components are critical for reducing friction between moving parts, thus enhancing the overall performance of machinery. However, the efficacy of ball bearings is heavily influenced by the lubrication used. Proper lubrication not only minimizes wear and tear but also significantly extends the lifespan of these components. This article delves into the vital role of lubrication in ball bearings, discussing various types of lubricants, their benefits, and the best practices for maintaining optimal performance.

Understanding Lubrication and Its Types

Lubrication is a process that involves applying a substance to reduce friction between surfaces in mutual contact. It is crucial for preventing wear and tear and maintaining the integrity of mechanical components. In relation to ball bearings, lubrication serves multiple functions, including reducing friction, dissipating heat, and preventing the entry of contaminants.

Types of Lubricants

There are two primary types of lubricants used in ball bearings: **grease** and **oil**. Each type has its unique properties and applications, making them suitable for different environments and operational requirements.

1. **Grease**: Grease is a semi-solid lubricant composed of a base oil thickened with a soap or other thickening agent. It provides excellent adhesion to surfaces, offering effective lubrication even in conditions where oil might wash away. Grease is ideal for applications requiring a longer-lasting solution that can withstand high pressures and loads.

2. **Oil**: Oil lubricants come in various viscosities and formulations, including mineral, synthetic, and biodegradable options. They are particularly effective in applications involving high-speed operations, as they provide superior lubrication and heat dissipation. Oils can also flow more freely, allowing for better coverage of the bearing surfaces.

Grease vs. Oil: Which Is Better?

Choosing between grease and oil depends on several factors, including the operating environment, load conditions, and specific application requirements. Grease is often favored for its ability to stay in place, making it suitable for applications where contamination is a concern. On the other hand, oil provides better cooling and lubrication in high-speed applications. Understanding the pros and cons of each lubricant type is essential for optimizing bearing performance.

The Importance of Lubrication in Ball Bearings

The significance of lubrication in ball bearings cannot be overstated. Proper lubrication is critical for ensuring that bearings operate efficiently and have a long service life. Here are a few key reasons why lubrication is vital:

- **Friction Reduction**: Lubrication creates a film between the moving parts, significantly reducing friction. This reduction is crucial for enhancing the efficiency of machinery and prolonging the lifespan of the bearings.

- **Wear Prevention**: Continuous lubrication prevents metal-to-metal contact, which can lead to wear and tear. By minimizing direct contact, lubrication helps maintain the structural integrity of the bearing components.

- **Contaminant Protection**: Lubricants act as barriers against dust, dirt, and moisture, which can significantly hinder the performance of ball bearings. Proper lubrication ensures that contaminants do not enter the bearing assembly, preserving its functionality.

Impact of Lubrication on Bearing Performance

Ball bearings are subject to various forces and conditions during operation. The right lubrication strategy is essential for optimizing performance. Here are some of the ways lubrication impacts ball bearing functionality:

Friction Reduction

One of the primary benefits of lubrication is its ability to reduce friction. High friction levels can lead to overheating and premature failure of bearings. Properly lubricated ball bearings experience less resistance, allowing them to operate more efficiently and with reduced energy consumption.

Heat Dissipation

As bearings operate, they generate heat due to friction. Effective lubrication helps dissipate this heat, maintaining optimal operating temperatures. This heat dissipation is crucial for preventing thermal degradation of the lubricant and the bearing materials.

Contamination Protection

Lubricants serve as a shield against contaminants, which can enter bearing assemblies and cause damage. The right lubricant can help exclude harmful particles, ensuring that bearings function smoothly and effectively over time.

Best Practices for Lubrication Maintenance

To maximize the benefits of lubrication, it is essential to adopt best practices for lubrication maintenance. Here are some recommendations:

- **Regular Lubrication Schedule**: Establish a regular lubrication schedule based on the operating conditions and the manufacturer's recommendations. Consistent lubrication helps maintain optimal performance.

- **Check Lubricant Levels**: Regularly monitor lubricant levels and ensure that they are within the recommended range. Low lubricant levels can lead to inadequate protection and increased wear.

- **Use the Right Lubricant**: Select the appropriate lubricant based on the application requirements, including load, speed, and environmental conditions. Always refer to manufacturer specifications when choosing lubricants.

- **Cleanliness is Key**: Keep the bearing assembly clean and free from contaminants. Proper sealing and cleaning practices help extend the life of the lubricant and the bearings.

Common Lubrication Mistakes to Avoid

While lubrication is essential for optimal bearing performance, several common mistakes can lead to problems. Here are some pitfalls to avoid:

- **Over-Lubrication**: Applying too much lubricant can lead to excess pressure within the bearing, causing seals to fail and leading to lubricant leakage.

- **Using Incorrect Lubricants**: Always use lubricants that are compatible with the specific application and bearing type. Using the wrong lubricant can lead to reduced performance and component failure.

- **Neglecting Routine Maintenance**: Regular maintenance is crucial for ensuring that bearings operate efficiently. Skipping lubrication schedules can result in increased wear and early failure.

Frequently Asked Questions (FAQs)

1. How often should I lubricate ball bearings?

The frequency of lubrication depends on several factors, including operating conditions, load, and the type of lubricant used. Follow manufacturer recommendations and observe the performance of your bearings to determine an appropriate schedule.

2. What is the best lubricant for ball bearings?

The best lubricant varies based on the application. Generally, high-quality grease or oil that matches the manufacturer's specifications is recommended. Consider factors such as temperature, speed, and load when selecting a lubricant.

3. Can I mix different types of lubricants?

Mixing different lubricants is generally not recommended, as it can lead to chemical reactions that reduce effectiveness. Always refer to manufacturer guidelines before combining lubricants.

4. What are the signs of inadequate lubrication in ball bearings?

Signs of inadequate lubrication include excessive noise, overheating, vibration, and visible wear on bearing surfaces. Regular monitoring and maintenance can help identify these issues early.

5. Is synthetic oil better than mineral oil for lubrication?

Synthetic oils often provide better performance in extreme conditions, including higher temperatures and pressures. However, the choice between synthetic and mineral oil should be based on the specific application and manufacturer recommendations.

Conclusion

In conclusion, lubrication plays a critical role in enhancing the performance and longevity of ball bearings. By understanding the types of lubricants available, the importance of proper lubrication, and best practices for maintenance, we can significantly improve the efficiency and durability of industrial equipment. Regular monitoring and adhering to a well-defined lubrication schedule are essential steps toward preventing costly downtime and ensuring the smooth operation of machinery. Ultimately, investing in proper lubrication strategies will yield long-term benefits in performance, reliability, and cost-effectiveness.

Related recommend

Share