Understanding Deep Groove Ball Bearings: Essential Insights for Industrial Applications

Time:

2024-10-12

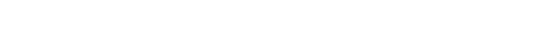

Deep groove ball bearings are among the most widely used types of bearings in industrial applications. Their simple design, efficiency, and versatility make them suitable for a range of machinery, from electric motors to automotive components. Understanding the features and advantages of deep groove ball bearings can significantly benefit professionals working with industrial equipment.

One of the primary characteristics of deep groove ball bearings is their structure, which consists of an inner and outer ring, balls, and a cage. The deep raceway grooves enable these bearings to accommodate both radial and axial loads, allowing for smooth and efficient operation even under high-speed conditions. This versatility makes them appropriate for applications where space is limited, and significant load-carrying capacity is required.

The operational efficiency of deep groove ball bearings stems from their ability to reduce friction. The balls roll between the inner and outer rings, minimizing sliding contact and enhancing wear resistance. This leads to longer service life and lower energy consumption, making these bearings a cost-effective choice for many applications.

In terms of installation, deep groove ball bearings require precise alignment and proper lubrication to function optimally. The lubrication can be provided through grease or oil, depending on the operational environment and speed requirements. Regular maintenance is essential to prevent contamination and ensure that the lubricant remains effective. A clean and well-lubricated bearing can significantly extend its lifespan and improve the overall efficiency of the machinery.

Moreover, it’s crucial to select the right size and load rating for a deep groove ball bearing corresponding to the application's specific requirements. Overloading a bearing can lead to premature failure, while under-loading may not utilize the bearing's full potential. Consulting with a bearing specialist or referencing manufacturer guidelines can help in determining the correct specifications needed for your application.

Deep groove ball bearings also come in various designs, including sealed or shielded options. Sealed bearings offer the advantage of being pre-lubricated and protected from contaminants, making them suitable for harsh environments. Shielded bearings, on the other hand, provide a balance of protection and ease of maintenance.

In conclusion, deep groove ball bearings are integral components in the industrial sector, renowned for their reliability and efficiency. By understanding their design, installation, and maintenance, professionals can ensure optimal performance and longevity in their machinery. Whether you are involved in manufacturing, automotive, or any other industry reliant on rotating equipment, recognizing the value of deep groove ball bearings will enhance your operational capabilities.

One of the primary characteristics of deep groove ball bearings is their structure, which consists of an inner and outer ring, balls, and a cage. The deep raceway grooves enable these bearings to accommodate both radial and axial loads, allowing for smooth and efficient operation even under high-speed conditions. This versatility makes them appropriate for applications where space is limited, and significant load-carrying capacity is required.

The operational efficiency of deep groove ball bearings stems from their ability to reduce friction. The balls roll between the inner and outer rings, minimizing sliding contact and enhancing wear resistance. This leads to longer service life and lower energy consumption, making these bearings a cost-effective choice for many applications.

In terms of installation, deep groove ball bearings require precise alignment and proper lubrication to function optimally. The lubrication can be provided through grease or oil, depending on the operational environment and speed requirements. Regular maintenance is essential to prevent contamination and ensure that the lubricant remains effective. A clean and well-lubricated bearing can significantly extend its lifespan and improve the overall efficiency of the machinery.

Moreover, it’s crucial to select the right size and load rating for a deep groove ball bearing corresponding to the application's specific requirements. Overloading a bearing can lead to premature failure, while under-loading may not utilize the bearing's full potential. Consulting with a bearing specialist or referencing manufacturer guidelines can help in determining the correct specifications needed for your application.

Deep groove ball bearings also come in various designs, including sealed or shielded options. Sealed bearings offer the advantage of being pre-lubricated and protected from contaminants, making them suitable for harsh environments. Shielded bearings, on the other hand, provide a balance of protection and ease of maintenance.

In conclusion, deep groove ball bearings are integral components in the industrial sector, renowned for their reliability and efficiency. By understanding their design, installation, and maintenance, professionals can ensure optimal performance and longevity in their machinery. Whether you are involved in manufacturing, automotive, or any other industry reliant on rotating equipment, recognizing the value of deep groove ball bearings will enhance your operational capabilities.

Related recommend

Share