Breaking Down the Benefits of Utilizing the Largest Ball Bearings

Time:

2024-10-16

Breaking Down the Benefits of Utilizing the Largest Ball Bearings

Table of Contents

- Introduction to Ball Bearings

- Understanding Ball Bearings

- What Are Large Ball Bearings?

- Benefits of Utilizing the Largest Ball Bearings

- Enhanced Load Capacity

- Improved Operational Efficiency

- Reduced Friction and Wear

- Extended Service Life

- Applications of Large Ball Bearings

- Choosing the Right Ball Bearing for Your Needs

- Maintenance Tips for Large Ball Bearings

- Frequently Asked Questions

- Conclusion

Introduction to Ball Bearings

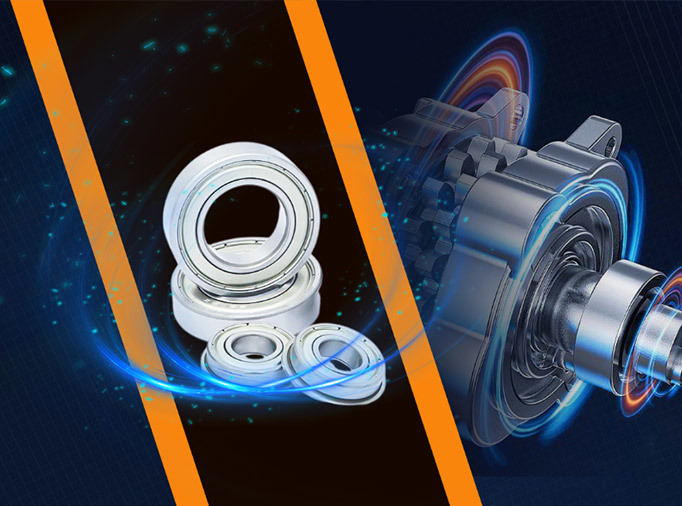

In the realm of industrial machinery, **ball bearings** play a pivotal role in ensuring smooth operations. These small yet formidable components reduce friction between moving parts, allowing machinery to function efficiently. While various types of bearings exist, **large ball bearings** stand out for their unique benefits. In this article, we explore the myriad advantages of utilizing the largest ball bearings, focusing on their significance across various applications.

Understanding Ball Bearings

Ball bearings consist of spherical elements positioned between two rings, known as races. These bearings facilitate rotational or linear movement, making them indispensable in numerous applications. By distributing loads evenly, they minimize wear and tear, extending the lifespan of machinery. To appreciate the benefits of large ball bearings, it's essential to understand their construction and mechanics.

What Are Large Ball Bearings?

Large ball bearings are designed to accommodate higher loads and provide greater durability than their smaller counterparts. These bearings are typically used in heavy machinery and industrial equipment, where performance and reliability are paramount. The size of these bearings allows them to support substantial loads while maintaining operational efficiency.

Benefits of Utilizing the Largest Ball Bearings

When it comes to industrial applications, the advantages of large ball bearings cannot be overstated. Below, we delve into some of the most compelling benefits of utilizing these robust components.

Enhanced Load Capacity

One of the most significant advantages of large ball bearings is their enhanced load capacity. The larger size and design allow them to bear greater weights without compromising performance. This capability is particularly beneficial in industries such as construction, manufacturing, and transportation, where heavy loads are the norm.

Improved Operational Efficiency

Large ball bearings contribute to improved operational efficiency by reducing the friction generated during machinery operation. Less friction translates to less energy consumption, which can lead to lower operational costs. Industries that prioritize energy efficiency can significantly benefit from switching to larger ball bearings, enhancing both their sustainability and profitability.

Reduced Friction and Wear

The design of large ball bearings allows for a smoother and more efficient movement of parts. This reduction in friction not only improves performance but also minimizes wear and tear, leading to lower maintenance costs and longer machinery life. By investing in large ball bearings, businesses can reduce downtime caused by mechanical failures, ultimately enhancing productivity.

Extended Service Life

The durability of large ball bearings is another noteworthy benefit. Their robust construction and ability to handle high loads and resist wear make them a long-lasting solution for industrial applications. Many companies have reported extended service life after switching to larger bearings, reducing the frequency of replacements and maintenance interventions.

Applications of Large Ball Bearings

Large ball bearings are utilized in a wide array of applications, reflecting their versatility and reliability. Here are some prominent sectors where large ball bearings are essential:

1. Construction Equipment

Heavy-duty machinery such as excavators, bulldozers, and cranes rely heavily on large ball bearings to maintain operational efficiency and handle substantial loads.

2. Aerospace

In the aerospace industry, precision is crucial. Large ball bearings support the mechanisms of aircraft engines, landing gear, and other essential components, ensuring safety and reliability.

3. Automotive

The automotive industry utilizes large ball bearings in various components, including wheel hubs and transmission systems, to enhance performance and durability.

4. Manufacturing Machinery

From conveyor systems to robotic arms, large ball bearings are integral to the manufacturing process, facilitating smooth movement and reducing downtime.

Choosing the Right Ball Bearing for Your Needs

Selecting the appropriate ball bearing is critical for optimizing performance. Consider the following factors:

1. Load Capacity

Evaluate the maximum load the bearing will be subjected to during operation. Choosing a bearing with a suitable load capacity will prevent premature failure.

2. Speed Requirements

Consider the speed at which the machinery operates. Different bearings are designed for specific speed ranges, so it's essential to select one that meets your operational needs.

3. Environmental Conditions

Take into account the operating environment. Factors such as temperature, humidity, and exposure to contaminants can affect bearing performance. Select bearings that are designed to withstand the specific conditions of your application.

4. Maintenance Needs

While large ball bearings are generally low-maintenance, understanding the required maintenance for different types can ensure longevity.

Maintenance Tips for Large Ball Bearings

Proper maintenance is vital for maximizing the lifespan and efficiency of large ball bearings. Here are some essential maintenance tips:

1. Regular Lubrication

Ensure that the bearings are regularly lubricated to reduce friction and prevent overheating. Follow manufacturer guidelines for lubrication intervals and types.

2. Inspection

Conduct routine inspections to identify signs of wear, damage, or contamination. Early detection can prevent more extensive issues down the line.

3. Cleanliness

Maintain a clean working environment. Contaminants can compromise bearing performance, so ensure that the area around the bearings is free from debris and dirt.

4. Monitor Operating Conditions

Keep an eye on the operational conditions that the bearings are subjected to. Excessive heat or load can lead to premature failure.

Frequently Asked Questions

1. What is the main advantage of using large ball bearings?

The primary advantage of large ball bearings is their enhanced load capacity, which allows them to support heavier loads while maintaining operational efficiency.

2. How do large ball bearings reduce maintenance costs?

Large ball bearings reduce maintenance costs by minimizing wear and tear, leading to longer service life and fewer replacements.

3. Are large ball bearings suitable for high-speed applications?

Yes, large ball bearings can be designed to accommodate high-speed applications, but it's essential to select the right type based on operational requirements.

4. What factors should I consider when choosing ball bearings?

Consider load capacity, speed requirements, environmental conditions, and maintenance needs when selecting ball bearings.

5. How can I ensure the longevity of large ball bearings?

Regular lubrication, routine inspections, maintaining cleanliness, and monitoring operating conditions are key to ensuring the longevity of large ball bearings.

Conclusion

Utilizing the largest ball bearings offers substantial benefits that can enhance operational efficiency, reduce costs, and prolong the lifespan of machinery. By understanding their advantages and applications, businesses can make informed decisions that significantly impact their performance and reliability. Whether in construction, aerospace, automotive, or manufacturing, large ball bearings are an investment that pays off in the long run. Embrace the advantages of these robust components to propel your industrial operations toward success.

Related recommend

Share